NOMOS is proud to call Glashütte its home—a small town tucked away between forests and hills, south of Berlin and near Dresden, located in the eastern Ore Mountains. The timepieces made here are world famous, and the watchmakers also count among the very best of their kind.

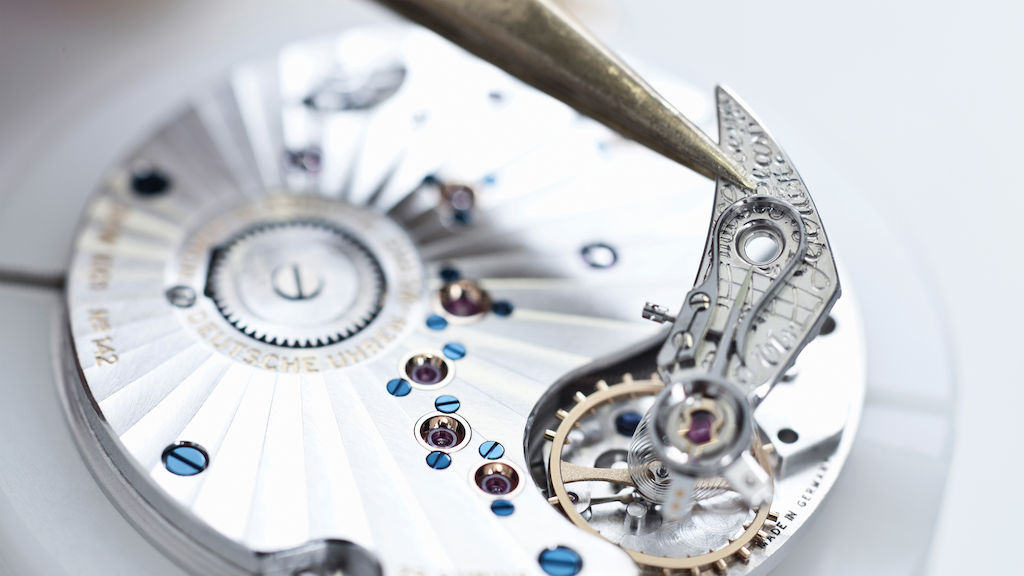

In March 2014 a sensation was unveiled: the heart of a watch’s caliber, engineered and built by NOMOS Glashütte. In watchmaking it is also known as the escapement—at NOMOS Glashütte it is called the swing system.

Landing on the moon, NOMOS style

A unique characteristic in the world of fine watches: the tempered blue balance spring, at work in the NOMOS swing system.

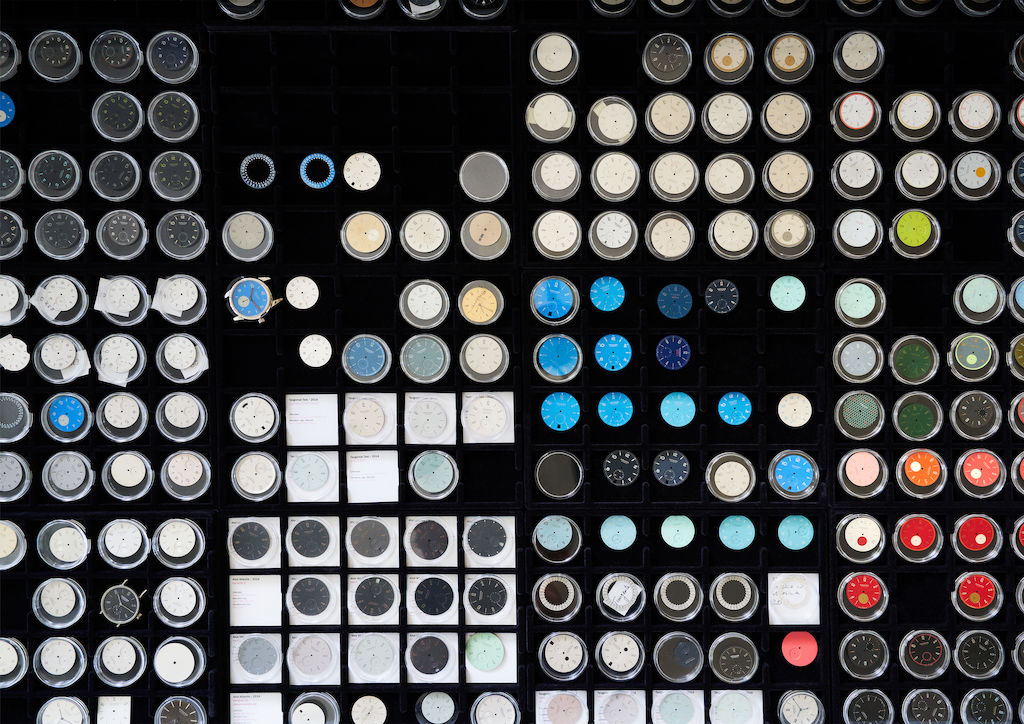

A glimpse of the watchmaking workshops in the chronometry building, high up in the valley. The majority of work is done by hand.

» NOMOS breaks the Swatch monopoly « Frankfurter Allgemeine Zeitung

But wait, there’s more:

The gold watches from the NOMOS Atelier

Next level watchmaking from NOMOS Glashütte: In addition to the renowned collection of stainless steel watches, the watchmaking company has produced its own series of golden haute horlogerie timepieces since 2013—each one a work of fine watchmaking art.

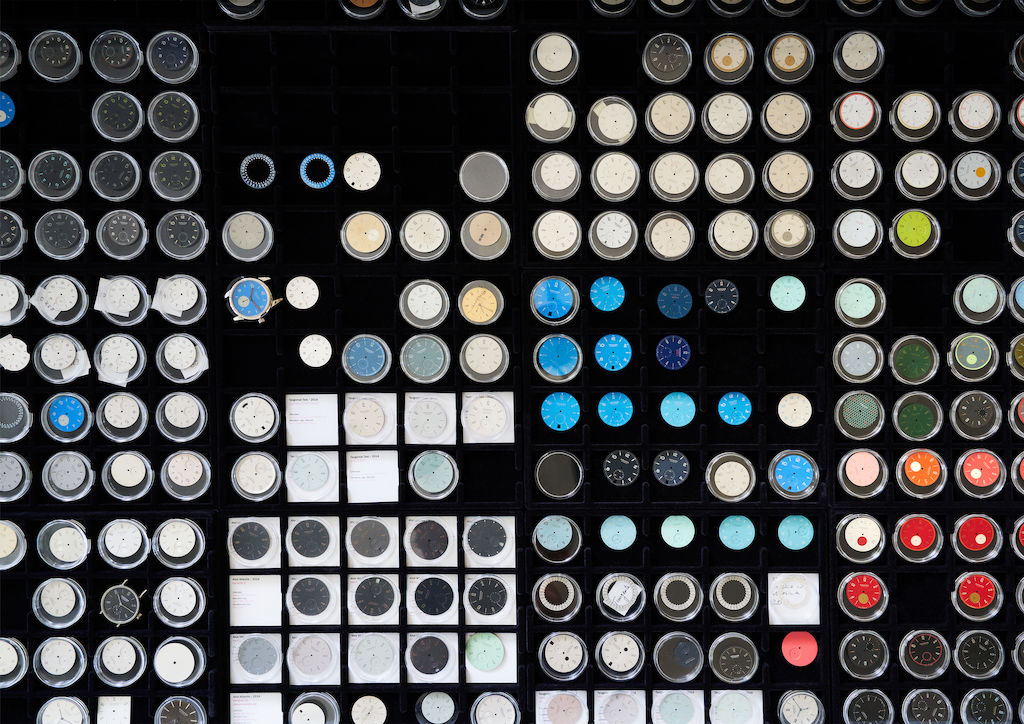

Glashütte miracle movements

Hand-beveled edges—and a small hand-engraved greeting from the watchmaker: the balance cock in a NOMOS gold watch.

Bringing the perfect shine to ratchet springs—they are black polished by hand.

Workshops

Look over the watchmakers' shoulders

We could tell you many things. But what do others say?

Discover next